Welcome to our comprehensive Q&A section following our recent webinar on AI denoising techniques for Non-Destructive Testing (NDT). During the session, we explored the advancements in deep learning algorithms specifically designed to enhance imaging quality by reducing noise in X-ray and other imaging modalities. Sara Ziliani, PhD, addressed various questions from participants, shedding light on the underlying technologies, methodologies, and real-world denoising applications.

In this Q&A page, you’ll find detailed responses covering key topics, including the types of neural network architectures employed, the challenges posed by multi-material components, and the integration of noise maps into training datasets. Whether you are looking to understand the technical aspects of our approach or the practical implications for your NDT processes, this resource aims to provide valuable insights and clarifications.

We appreciate all participants for their engaging questions and encourage you to explore the details below for a deeper understanding of denoising techniques in NDT.

Neural Network Architecture and Training

Which type of neural network architecture are you using? Any kind of convolutional autoencoder?

We use a convolution neural network that is not a convolutional autoencoder type. Autoencoder types can compress information and extract image features, but it is often difficult to recover a detailed structure.

Could you please explain the training procedure of the neural network again?

To train the deep-learning algorithm, we need to provide an input (the starting point) and a teacher (the goal) data set. In the case of the de-noising, the input data set is real or simulated X-ray images, while the noise component (real or simulated) is the teacher data set. The training then proceeds with an iterative process, where the algorithm's internal parameters are changed iteration after iteration until the algorithm can recognize the noise in the input images.

Does the customer need to train the algorithm?

No, the algorithm is trained by Hamamatsu.

What is the role of the noise map in the training? How is it incorporated into the dataset?

The role of the noise map is like an assist function that enables the AI to remove noise correctly. As a specific example, there is a case where the noise value changes when the X-ray imaging conditions or camera's gain setting change, even though the camera output signal is the same. In such cases, it can be difficult for the AI to determine whether it is noise or signal (structure). To solve this problem, the AI can remove noise components better by providing a noise value (noise map) for each pixel in a simulation calculation as input information. The dataset is incorporated as a 2-channel image + noise map. Therefore, the noise map needs to be given as input in the inference phase as well.

AI De-noise technology

Are you able to remove only statistical noise or also structural noise?

Depending on the training data, the technique can respond to structural noise as well. If structural noise can be reproduced by calculation, removal can be handled by including it in the training data.

Denoising seems to give some artifacts. Do you plan to correct it?

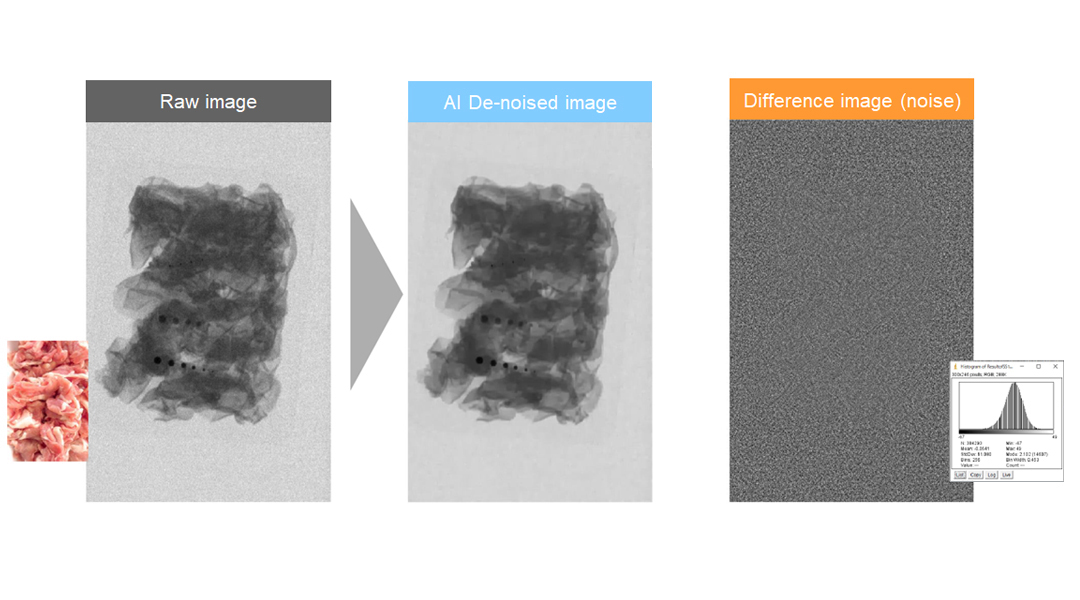

The component left behind by the AI noise reduction looks like an artifact. This is the difference between the noise generated by the simulation and the actual noise. Furthermore, in real cameras, the noise varies from model to model because the components are not always of the same quality. If the best performance is to be extracted, it can be assumed that transition learning with a small number of measured images will reduce the artifacts even further.

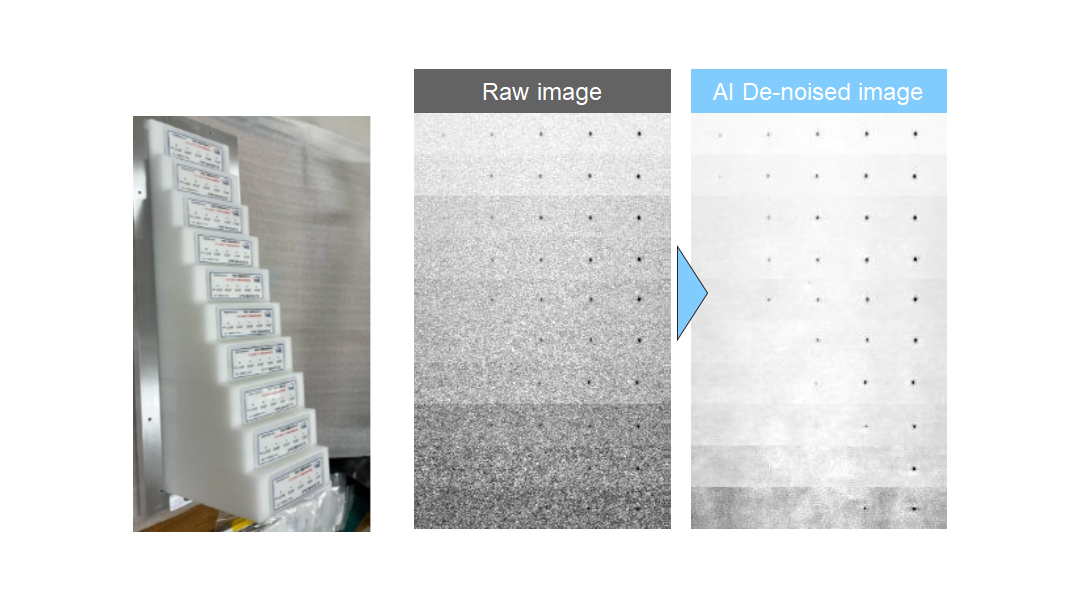

Technology validation with Camera C14300

Tube Voltage:50 kV, Tube Current:1.8 mA, FDD:350 mm, Sample:POM 10 mm - 100 mm,

Chart:SUS ball 0.3 mm - 0.7 mm

Raw pork image

Raw image: 0.1 mA @ 50 kV

Image Processing Techniques and Results

How do you make sure that the denoised results remain less blurry?

To avoid blurred results after de-noising, it is desirable to have skip connections such as ResNet or U-Net so that the detailed structure is not lost. Constraining the loss function to maximize the preservation of high-frequency components can enhance resolution maintenance.

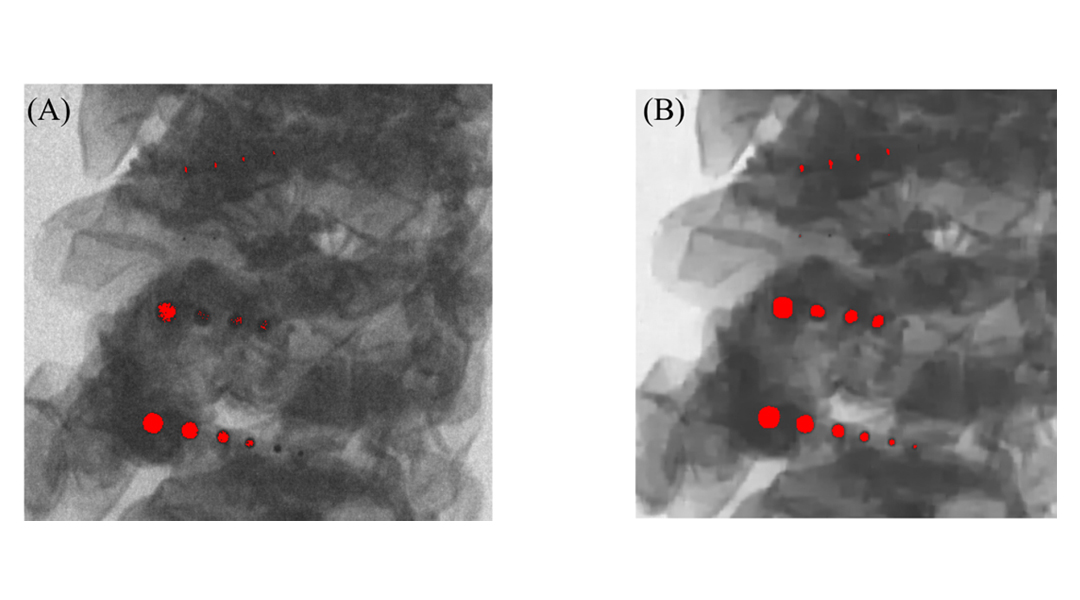

How do you see the contaminants (meat dataset) in greyscale images? What is the RED coloring?

X-ray images can be seen as matrices of numbers, where each number is associated to each image pixel and represents a level on a grey scale. One of the simplest methods to find contaminants is to set a threshold on the grey scale and highlight all the pixels whose grey value is lower/higher than the threshold with a color. In the case of the images shown in the presentation, the red areas have a lower grey value than the threshold. They are associated with the contaminants, which absorb more X-rays, resulting in darker image areas.

Contaminants detection through simple thresholding technique in raw pork image

How does AI de-noising perform compared to other advanced techniques, such as wavelet de-noising?

Various de-noising filters exist, such as wavelet de-noising, bilateral filters, and non-local mean filters, which can effectively remove linear noise. However, they are often inadequate at removing non-linear noise. The literature reports more specific comparison results: they show that AI noise reduction performs better in noise removal and resolution maintenance than other techniques.

Handling Radiation and Material Challenges

Can the software handle scatter radiation?

Scatter radiation is not considered in the image simulation since it would take too much processing time. To evaluate the scattered radiation, a particle transport code such as PHITS (Particle and Heavy Ion Transport Code System) shall be used in conjunction with the X-ray simulations.

Is it possible to apply the method to the radiographic films?

No, the technique can be applied only to Hamamatsu digital detectors.

What are the main challenges when you have multi-material components as absorption/transmission can be quite different between materials?

Calculating the transmission/absorption is possible by creating a CAD file for each material and associating the appropriate attenuation coefficient to each material. A compositional analysis can be performed to calculate the attenuation coefficients if the material is a mixture of several materials. The original data (attenuation coefficients) for each composition are available at the National Institute of Standards and Technology (https://www.nist.gov/).

Summary

Hamamatsu Photonics presents an advanced neural network-based approach for denoising X-ray images, highlighting the use of a convolutional neural network together with proprietary X-ray simulations, that effectively preserves image detail and structure. Although scatter radiation is not simulated due to computational limitations, the technique demonstrates its applicability to Hamamatsu digital detectors. The training process is clearly defined and involves both input images and corresponding noise data, with the incorporation of noise maps significantly enhancing AI performance. This method successfully addresses both statistical and structural noise despite challenges posed by multi-material components and artifacts that may arise post-denoising. Ultimately, this AI-driven approach is a superior choice to traditional denoising techniques, particularly in its ability to manage non-linear noise effectively.